Surge Valves Increase Application Efficiency

Related Articles

- 2010 Row Crop Short Course Video Links 0

- Key Corn Verification Findings 1

- What to Expect from Later than Normal Corn Planting 2

Latest Tweets

In 2014, t he Irrigation Team added surge valves to our list of tools to increase irrigation application efficiency. When using a surge valve, water is applied in a series of on-off cycles alternating between two irrigation sets. By utilizing surge valves Producers can expect reduced surface runoff, reduced deep percolation loss, and application inefficiencies 25% great than conventional irrigation techniques. In sealing silt loam soils improved infiltration rates h

he Irrigation Team added surge valves to our list of tools to increase irrigation application efficiency. When using a surge valve, water is applied in a series of on-off cycles alternating between two irrigation sets. By utilizing surge valves Producers can expect reduced surface runoff, reduced deep percolation loss, and application inefficiencies 25% great than conventional irrigation techniques. In sealing silt loam soils improved infiltration rates h ave been documented. Understanding the correct operation procedure and purchasing the correct surge valve is imperative to the success of deploying a surge valve.

ave been documented. Understanding the correct operation procedure and purchasing the correct surge valve is imperative to the success of deploying a surge valve.

Deciding on the correct surge valve to purchase is the first step in utilizing a surge valve. Before purchasing a surge valve, here are some considerations. Producers need to be aware of the limitations and capacity restraints of surge valves. Producers will need to select the proper valve based on the output of the well or riser. Based on the chart to the right, a 6″ surge valve has a capacity from 0 to approximately 700 GPM while the much larger 12″ will handle well capacities up to 2600 GPM.

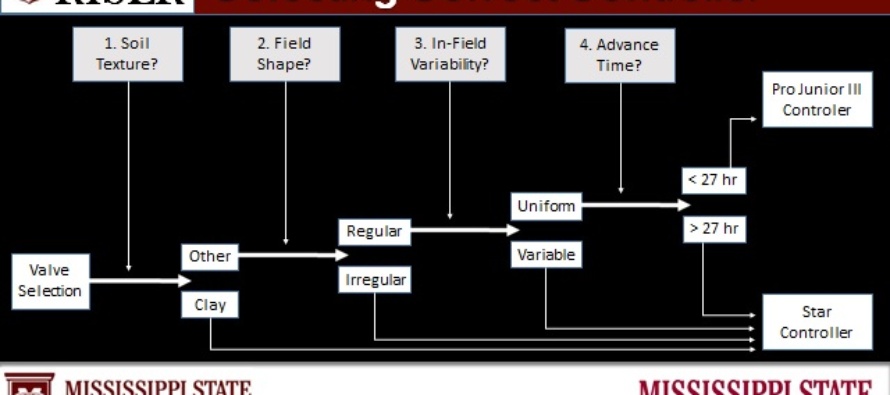

Producers also need to be aware of the limitation of the two types of valve controllers prior to purchase. P&R Surge Systems manufacture two surge valve controllers, the Star and the Jr.III.

Producers also need to be aware of the limitation of the two types of valve controllers prior to purchase. P&R Surge Systems manufacture two surge valve controllers, the Star and the Jr.III.  The Star controller is totally digital and much more flexible in programming. The Jr.III, being the more economic controller, lacks many of the features as of the top of the line, Star controller. If you are using a Jr.III you’ll need to understand its limitations. We have put together the following guide to assist Producers in the selection process. (the image is clickable for your convenience) You will notice that the only situation that a Jr.III controller is applicable is; a uniform, regular or square shaped field that a set is irrigable in less than 27 hours.

The Star controller is totally digital and much more flexible in programming. The Jr.III, being the more economic controller, lacks many of the features as of the top of the line, Star controller. If you are using a Jr.III you’ll need to understand its limitations. We have put together the following guide to assist Producers in the selection process. (the image is clickable for your convenience) You will notice that the only situation that a Jr.III controller is applicable is; a uniform, regular or square shaped field that a set is irrigable in less than 27 hours.

Phases of Furrow Irrigation

1. Advance Cycle – The phase in which the dry furrow is wetted. This cycle creates multiple pluses down the field.

2. Out Time – The time required for water to reach the end of the furrow.

3. Soaking Cycle – The phase in which the required application depth is infiltrated. This is a single pulse, with each pulse reaching the tail ditch.

4. Soaking Time – The time it takes the required application depth to infiltrate.

A video explaining these cycles can be seen here. http://www.youtube.com/watch?v=46sSLFBUrh8

The following are points to consider when setting up a surge valve:

If you have a silt loam or sandy soil that has a tendency to seal causing water infiltration to be an issue:

1. Determine the Out Time from past experience.

2. Set the Advance Cycle to ½ of the Out Time + one hour. For example, if you have a field that has historically required 24 hours to get the water across and you now have this same field set up with a surge valve, the Advance Cycle would be set to 13 hours.

3. It is critical that the time required for water to actually reach the tail ditch be recorded. Any adjustments to the Advance Cycle of the surge valve need to be made before the Soaking Cycle begins. You made need to add or subtract time from the original settings of the Advance Cycle. If you miss this timing, adjustments can only be made after the completion of the Soaking Cycle.

4. The Soaking Time or completion time can be found on your PHAUCET printout. If PHAUCET requires 20 hours to apply 3 acre inches on each set, then the total system run time is 40 hours before you shut the system and well off. It is equally important to adjust the Soaking Time, if the single pulse is falling short of the tail ditch, time should be added, if the single pulse is putting water in the ditch, time should be subtracted.

If you have a cracking clay soil:

When programing the advance cycle of the Star controller for a clay soil types, producers need to refer to the Phaucet or Pipe Planner printout for the time required to apply 3 acre inches and set the advance cycle accordingly.

For example, if the printout says that 22 hours are required to apply 3 acre inches, the advance cycle would be set for 22 hours. After setting the advance cycle time producers need to adjust the total number of cycles per side for the valve to complete. It is recommended to subtract two cycles from the value displayed on the controller, but never less than a total number of 3 cycles. Press the “custom” tab, lets say the controller displays 6 cycles per side, use the down arrow key to subtract 2 cycles from the number of cycles per side (#cycles/side). The display should display 6-2 (or 4 cycles per side) Never use less than 3 cycles per side, so if the controller displays 4 cycles per side, do not subtract the recommended two, use 4-1. (3 cycles per side) Please see example at bottom.

Let me tell You a sad story ! There are no comments yet, but You can be first one to comment this article.

Write a comment